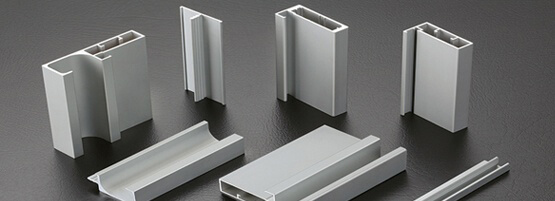

Aluminium Extrusion

Aluminium extrusion is the process where an ingot is pressed through a die by a press. After streamlining aluminium alloys to make a required shape of product.

How the method works

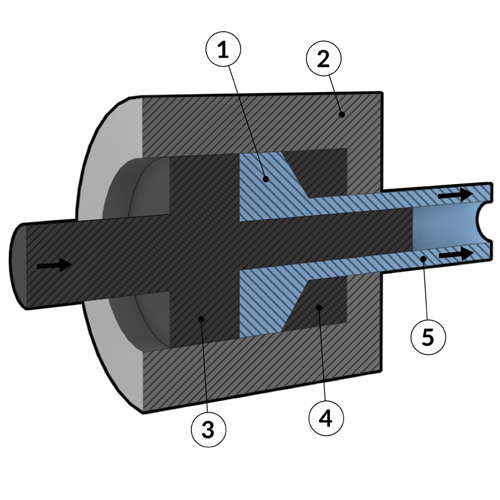

The working material consists of a preheated ingot [1] which is placed in a press chamber. A piston is pressed against the ingot with an applied pressing force which forces the ingot out through a die at the bottom of the press chamber. The ingot then assumes the same shape as the cross-sectional area of the matrix and is pressed out as a solid axially symmetrical rod.

The force required to force the ingot through the container is high due to the large friction between the ingot and the wall of the container. As the ingot is felled and becomes thinner, the force increases, which leads to the rear end of the ingot not being able to be pushed through the mould with the desired result. Due to this, the rear end can usually not be used.

Due to its divergent complimentary properties’ strength, lightweight and flexibility, aluminium is an alternate choice for numerous applications, compared to other metals.